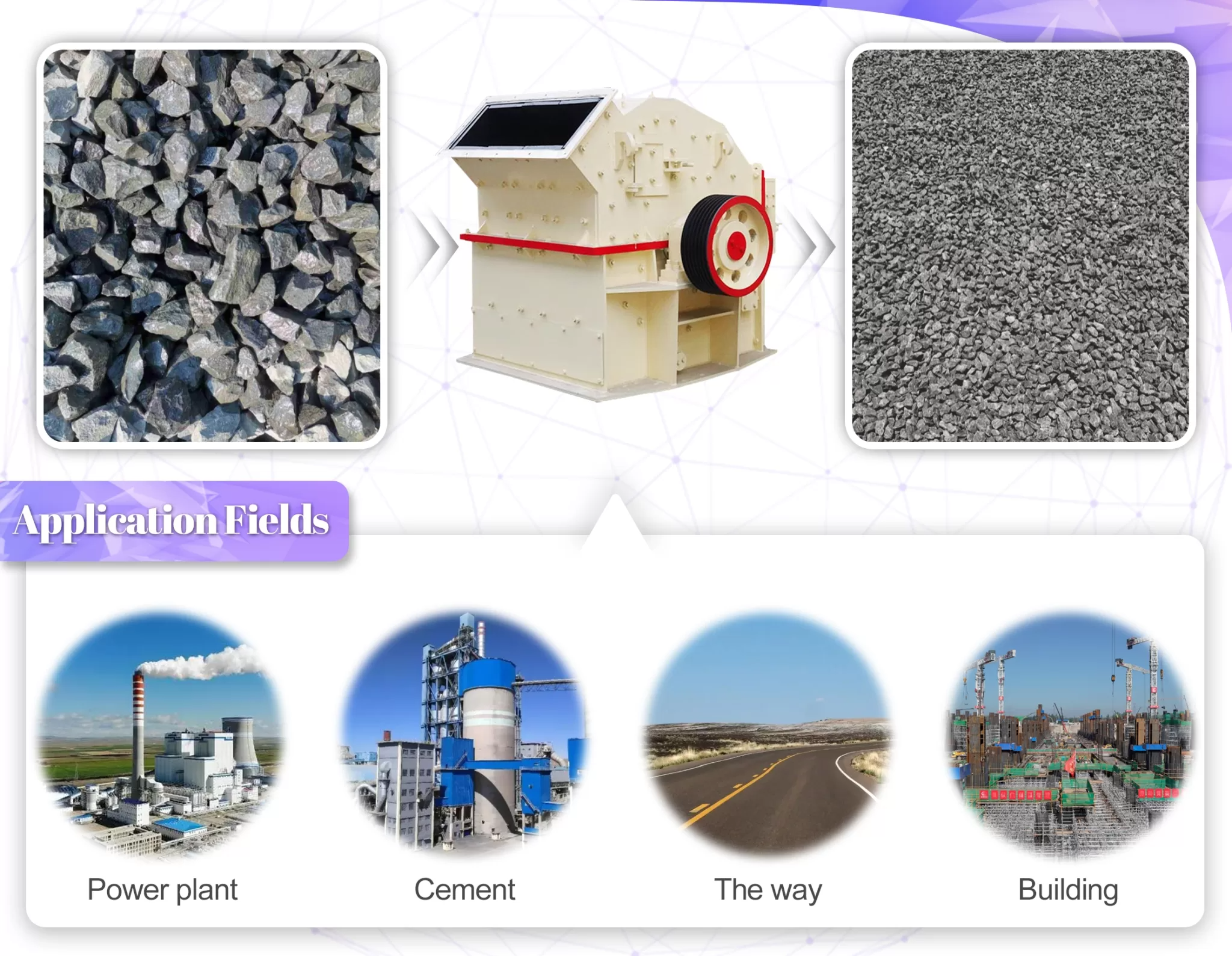

As a key fine crushing equipment in stone crushing production lines, the high-efficiency fine crusher plays an irreplaceable role in ore processing and manufactured sand production due to its superior fine crushing performance. It is a core piece of equipment for improving the efficiency of the entire production line and the quality of the finished product.

I. Core Role in Production

The high-efficiency fine crusher undertakes the crucial fine crushing and shaping tasks in the stone crushing process, connecting primary jaw crushers and other front-end crushing equipment with subsequent grinding equipment such as ball mills. It can further refine materials after coarse and medium crushing, reducing the average particle size to P80≤3-5mm, significantly improving the efficiency of subsequent grinding stages and reducing overall energy consumption.

In manufactured sand production, it combines sand making and shaping functions, processing raw materials such as river pebbles and granite into construction sand with excellent particle shape, ensuring that the aggregate meets the quality requirements of high-grade highways, railways, and other projects. Meanwhile, this equipment can be perfectly integrated with vibrating feeders, circular vibrating screens, and belt conveyors to create a highly efficient and smooth stone crushing production line.

II. Equipment Structural Advantages

Multi-chamber crushing design: Utilizing a three-chamber curved crushing chamber, it increases the number of material impacts, achieving efficient crushing through the "stone-on-stone" principle, reducing wear on hammers and liners, and extending the service life of vulnerable parts.

Intelligent adjustment and maintenance: Equipped with a hydraulic opening device and impact plate adjustment system, the output particle size can be easily adjusted without disassembling the machine casing, improving maintenance efficiency by 50% and effectively shortening downtime.

High-efficiency wear-resistant configuration: Employing a "sandwich" structure wear-resistant hammer and multi-element high-chromium alloy liners, wear resistance is improved by 3-5 times, reducing equipment operating costs and adapting to the crushing needs of medium-hard and extra-hard materials.

Dust-free intelligent operation: Optimized sealing structure and airflow self-circulation design create a dust-free crushing environment. Combined with an intelligent detection system, it can monitor the equipment's operating status in real time, automatically alarming and shutting down in case of abnormalities.

III. Wide Range of Applications The high-efficiency fine crusher is applicable to multiple industries, capable of processing various materials such as limestone, granite, basalt, and cement clinker. Materials with a compressive strength not exceeding 200MPa and a moisture content not exceeding 10% can be efficiently crushed. In the mining crushing equipment field, it is used in the fine crushing process before grinding; in the construction industry, it is adapted to construction waste crusher production lines to process recycled aggregates from construction waste; in water conservancy, airport, and municipal engineering fields, it provides high-quality aggregates for manufactured sand production. Furthermore, it can also be applied to the fine crushing of materials in the metallurgical, chemical, and refractory materials industries, achieving flexible configuration for multiple uses.

IV. Precisely Solving Core Customer Problems

Capacity and Efficiency Challenges: The crushing ratio can reach 25-30, simplifying tertiary crushing to secondary crushing, increasing output efficiency by 35%-50% compared to traditional equipment. Single-machine processing capacity can reach 50-500t/h, meeting the needs of different production scales.

Key Pain Points in Finished Product Quality: Through multiple impacts and friction grinding, the finished product has a cubic particle shape with extremely low needle-like and flaky content and a reasonable gradation, solving the problems of poor particle shape and unstable quality in traditional fine crushing equipment.

Energy Consumption and Cost Pressure: It saves 50% more energy than traditional fine crushers, reduces long-term operation and maintenance costs by 35%-50%, and extends the service life of wear-resistant parts, significantly reducing customers' investment and operating costs.

Environmental Compliance Requirements: The dust-free design meets environmental standards, effectively controlling dust pollution and helping customers achieve green production and meet stringent environmental policy requirements.

V. Comprehensive After-Sales Service Guarantee: We provide comprehensive after-sales service support for high-efficiency fine crushers, including one-stop service for equipment installation, commissioning, and operation training. Our professional technical team responds to maintenance needs 24/7, providing detailed maintenance manuals and remote technical guidance. We have established a complete spare parts supply system to ensure timely supply of wear-resistant hammers, liners, and other crusher parts, ensuring continuous and stable equipment operation. If you have any needs regarding high-efficiency fine crushers, please contact us, and we will recommend the best solution for you..