Magnesium Metal Rotary Kiln

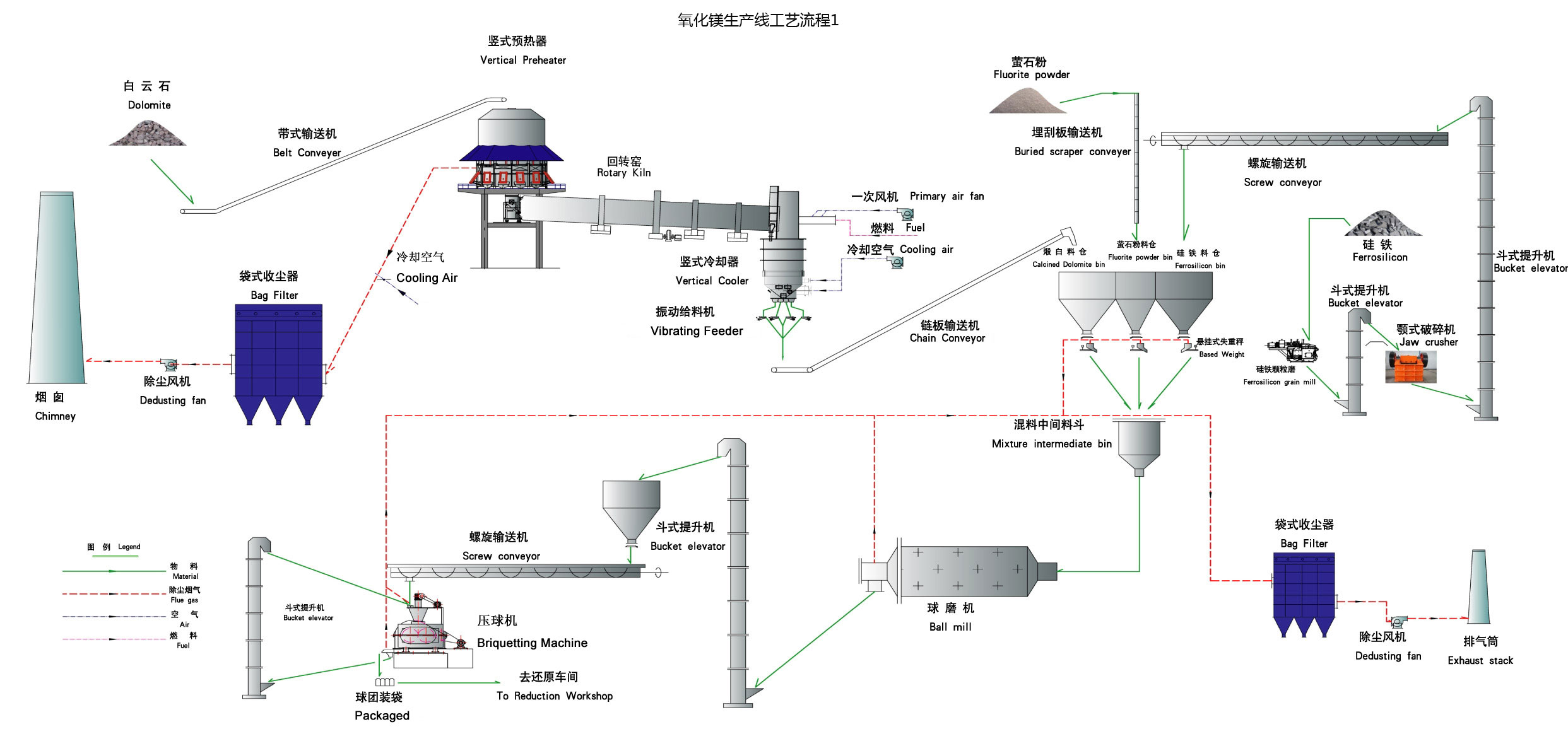

The raw material for the production of magnesium in the rotary kiln is dolomite. The dolomite is first crushed into 30-40mm materials by a crusher, then sintered by a metal magnesium rotary kiln, calcined into calcined white and then cooled by a cooler. After cooling, it is ground into powder by a ball mill, and the ball press presses the ground powder into balls. After crushing, it is mixed evenly with ferrosilicon powder containing 75% silicon and fluorite powder containing 95% GaF2 to form a ball, which is then loaded into a heat-resistant stainless steel reduction tank. In the reduction furnace at 1200-1250℃ and 1.33Pa vacuum, it is reduced to produce crude magnesium, and then refined by flux, cast ingots, and surface treated to obtain the finished magnesium ingot.

Advantages of the process of producing metal magnesium in the rotary kiln

1. Uniform heating and high purity of magnesium oxide During the calcination process of the magnesium oxide rotary kiln, the material is in a tumbling state, the heat is uniform, the temperature of the combustion device is easy to control, the calcination quality is good, the activity of the magnesium oxide product can reach 350-400ml, and the pollution is small, which is conducive to obtaining high-purity magnesium oxide.

2. Mechanization and large output The calcination process of magnesium oxide rotary kiln has a high degree of mechanization, the operation process is easy to control, the production processing volume is large, and it can meet the production needs of magnesium oxide production line.

3. Reliable operation and good quality The material is greatly worn in the magnesium oxide rotary kiln, and the product is powdery. There are high requirements for the strength of the raw materials. Some raw materials can be calcined in the vertical kiln to obtain better block materials. The magnesium oxide rotary kiln calcines metallurgy or active lime, and the unit product heat consumption is low, which is lower than the heat consumption of the countercurrent single-drum mechanized wet material vertical kiln.

4. High output and low energy consumption The magnesium oxide rotary kiln is more convenient to operate and reliable than traditional equipment. Compared with the equipment of the same specification, the operation rate is increased by 10%, the output is increased by 5%-10%, and the heat consumption is reduced by 15%.