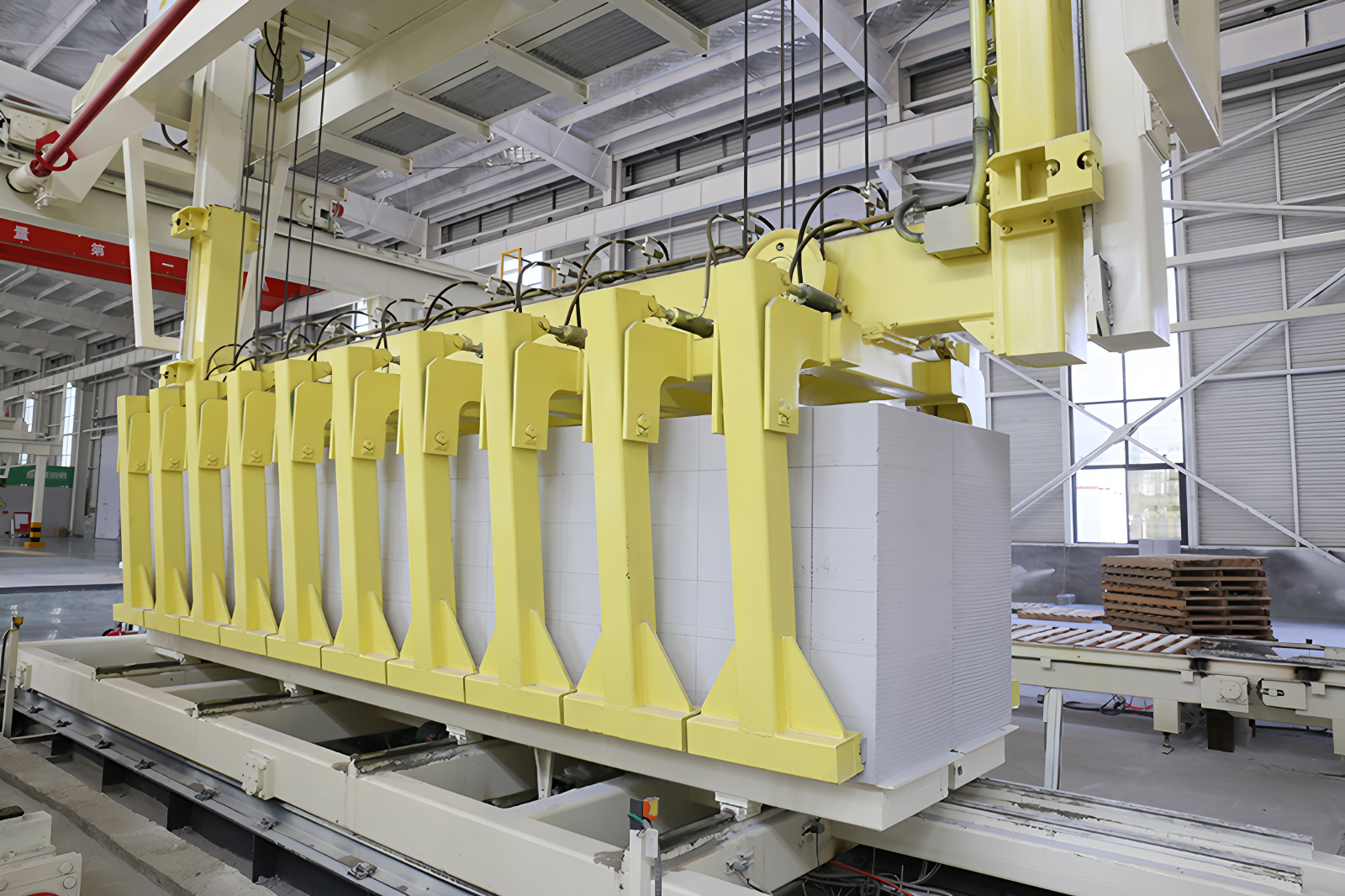

AAC (Aerated Concrete Brick Production Line) block separators are essential equipment for AAC block production and AAC production lines. As a key component of the AAC block forming machine, they work in conjunction with core equipment such as the slurry tank, pouring mixer, belt conveyor, and autoclave to ensure the smooth and efficient production of aerated concrete blocks, AAC blocks, and AAC bricks. Professional AAC block machine manufacturers and AAC plant manufacturers, such as Richi AAC Plant, integrate high-performance AAC block separators into their turnkey AAC block production plant solutions. This equipment is specifically designed to seamlessly separate cured or semi-cured aerated concrete blocks from molds, trays, or each other, directly impacting the yield, production efficiency, and final quality of aerated concrete products.

2. Aerated Concrete Block Separator: Core Functions and Importance

2.1 Core Functions of an Aerated Concrete Block Separator

The primary function of an aerated concrete block separator is to precisely and non-destructively separate aerated concrete blocks at various stages of production. The separator begins its operation after the aerated concrete slurry is poured into molds by a pouring mixer, initially sets, and is cut into standard sizes (consistent with the dimensions of the aerated concrete blocks) by a cutting machine or cured in an autoclave to form solid aerated concrete blocks. It separates aerated concrete blocks from the mold frames or trays that support them, and can also separate connected batches of blocks into individual aerated concrete blocks based on production needs. Advanced aerated concrete block separators are equipped with adjustable pressure and speed control systems that can be customized based on the density, size, and hardness of the aerated concrete blocks, ensuring compatibility with different types of aerated concrete products, including lightweight and high-strength aerated concrete blocks.

2.2 Importance in AAC Block Production Lines

AAC block separators play a crucial and irreplaceable role in the entire aerated concrete block production process. Without an efficient separator, aerated concrete blocks may stick to molds or pallets, resulting in block breakage, edge chipping, or surface damage during manual or mechanical removal. This not only increases the defect rate of aerated concrete blocks (failure to meet IS specifications for aerated concrete blocks) but also requires additional manual repair work, significantly reducing the production efficiency of the aerated concrete production line. For large-scale aerated concrete block plants and aerated concrete processing plants, a high-quality aerated concrete block separator ensures continuous production line operation, reduces mold and pallet turnaround time, and helps maintain consistent appearance and performance of aerated concrete blocks. It serves as a critical link between the cutting, curing, and packaging processes, laying a solid foundation for subsequent quality inspection, storage, and transportation of aerated concrete blocks.

3. AAC Block Separator Operation Process

3.2.1 Feeding and Positioning

First, the AAC blocks to be separated (held on pallets or formwork) are transported to the AAC block separator's feed area via a belt conveyor. The separator's positioning device (equipped with infrared or laser positioning sensors) precisely aligns the blocks with the separating components, ensuring that the separating force is applied at the correct location. This step is crucial, as inaccurate positioning can result in uneven force application, potentially damaging the blocks.

3.2.2 Separation Execution

After positioning, the separator's separator initiates the separation process according to preset parameters. To separate the blocks from the pallet, hydraulic push plates or vacuum suction cups act on the sides or bottom of the AAC blocks. The push plates apply a uniform force, while the suction cups generate a steady negative pressure to lift the blocks, separating them from the pallet surface. To separate connected blocks from a batch, thin, high-strength blades (adjusted to the size of the AAC blocks) are inserted into the pre-cut gaps between the blocks, applying gentle pressure to separate them. Throughout the process, pressure and speed sensors continuously monitor operational data, enabling the control system to adjust in real time to avoid excessive force.

3.2.3 Post-Separation Processing

After successful separation, the AAC blocks are transported by an output belt conveyor to the next process step (e.g., quality inspection of the AAC blocks' density, strength, and appearance). The separated pallets or formwork are briefly cleaned (to remove residual slurry) and then returned to the front-end casting process for recycling, completing the production line's cycle. After completing a separation cycle, the AAC block separator automatically resets and prepares for processing the next batch of blocks.

4. Advantages of High-Quality AAC Block Separators

4.1 Ensuring AAC Block Quality and Reducing Defects

High-performance AAC block separators offer exceptional adaptability. They can be adjusted to accommodate various AAC block parameters, such as AAC block size (from small standard blocks to large custom blocks), AAC block density (500-800 kg/m³), and AAC block type (standard AAC blocks, refractory AAC blocks, etc.). This makes them suitable for a variety of AAC production lines, including automated AAC lines, autoclaved sand-lime brick lines, and AAC block lines using fly ash or sand as raw materials. For AAC block machinery manufacturers and AAC plant manufacturers, this versatility enables integration into various turnkey project solutions to meet the diverse needs of global customers.

5. Selection and Maintenance of AAC Block Separators

5.1 Key Selection Criteria

When selecting an AAC block separator for an AAC block production line or AAC block plant, the following key factors should be considered to ensure it matches your production needs:

Capacity Matching: The separator's separation speed and processing capacity should match the total output of the AAC line. For high-capacity aerated concrete plants (over 100,000 cubic meters per year), a high-speed, multi-station aerated concrete block separator is recommended. For small to medium-sized aerated concrete block production plants, a medium-efficiency, single-station separator will suffice.

Adaptability to aerated concrete block specifications: The separator should be adaptable to different aerated concrete block sizes, densities, and types. It's important to confirm whether the manufacturer can provide customized separator parameters based on the specific AAC product being produced (e.g., ultra-lightweight or large-sized AAC blocks).