Process Design and Equipment Configuration for a Manufactured Sand and Gravel Aggregate Production Line

Process Design and Equipment Configuration for a Manufactured Sand and Gravel Aggregate Production Line

Due to its stable quality and adjustable grading, manufactured sand and gravel aggregates have become core raw materials for infrastructure projects. The process design and equipment configuration of its production line directly determine the quality of the finished product and production efficiency. The following details the process flow and core equipment selection logic, using a typical high-yield configuration of "three-stage crushing + sand shaping + multi-stage screening" as an example.

I. Core Process Design (Using Granite/Limestone as an Example)

1. Raw Material Pretreatment: Quality and Quantity Control, Impurity Removal

Raw materials (particle size ≤1000mm) are first stored in a raw material silo and evenly transported to the pretreatment stage via a vibrating feeder. The core of this stage is "impurity removal and grade control." If the raw material contains more than 5% mud or contains plant roots, pre-screening with a drum stone washer or vibrating screen is necessary to remove dirt, dust, and impurities with a particle size of less than 5mm to prevent subsequent equipment clogging and wear. If the raw material particle size varies greatly (some exceeding 1200mm), a heavy hammer crusher can be used for "pre-crushing before coarse crushing" to reduce oversized material to the jaw crusher's handling range and reduce the load on the jaw crusher.

2. Primary Crushing: Size Reduction and Crushing, Laying the Foundation

After pretreatment, the raw materials enter the primary crushing system. The core objective is to reduce bulky raw materials to "medium crushing-suitable materials" with a particle size of ≤150mm, forming a stable "feeding-crushing-temporary storage" process.

A jaw crusher is used as the core equipment (the feed port size is selected based on the maximum raw material particle size, e.g., a 1200×1500 jaw crusher is suitable for raw materials ≤1000mm). It utilizes the "extrusion crushing" principle to achieve efficient size reduction, achieving a crushing ratio of 4-8. The processing capacity is adapted to the production line capacity (e.g., a 500 t/h production line is equipped with two PE1000×1200 jaw crushers). After primary crushing, the material is conveyed by belt conveyor to an intermediate stockpile (steel silo or open-air stockpile) for temporary storage. The stockpile capacity must meet the production needs of downstream equipment for 2-4 hours (e.g., a 500 t/h production line is equipped with two PE1000×1200 jaw crushers). The ton-line stockpile volume (≥1000m³) can buffer against fluctuations in raw material supply and equipment maintenance, ensuring continuous production line operation.

3. Secondary Crushing: Graded Crushing and Optimized Grading

The material from the intermediate stockpile is evenly conveyed to the secondary crushing system via a vibrating feeder. The core of this process is "pre-screening + closed-circuit crushing" to avoid over-crushing and control the feed particle size.

First, pre-screening: A three-deck vibrating screen (with mesh sizes of 80mm, 20mm, and 5mm) separates the material into three categories: material >80mm enters the secondary crushing unit, material 20-80mm goes directly to the sand-forming process, and material <20mm enters a temporary storage bin before final product screening.

Second, secondary crushing: A cone crusher (spring cone crusher for medium-hard materials, hydraulic cone crusher for hard rock) is used. This system forms a closed-circuit system with the pre-screening process. After the cone crusher crushes the material (particle size ≤80mm), it returns to the pre-screener for re-screening to ensure a stable gradation after secondary crushing.

During this stage, the discharge particle size can be controlled by adjusting the cone crusher discharge opening size (typically set to 20-30mm), while the undersize <5mm is screened. The stone powder can be collected separately and used as raw material for construction, improving raw material utilization.

4. Sand Shaping Stage: Shaping, Quality Improvement, and Particle Shape Control

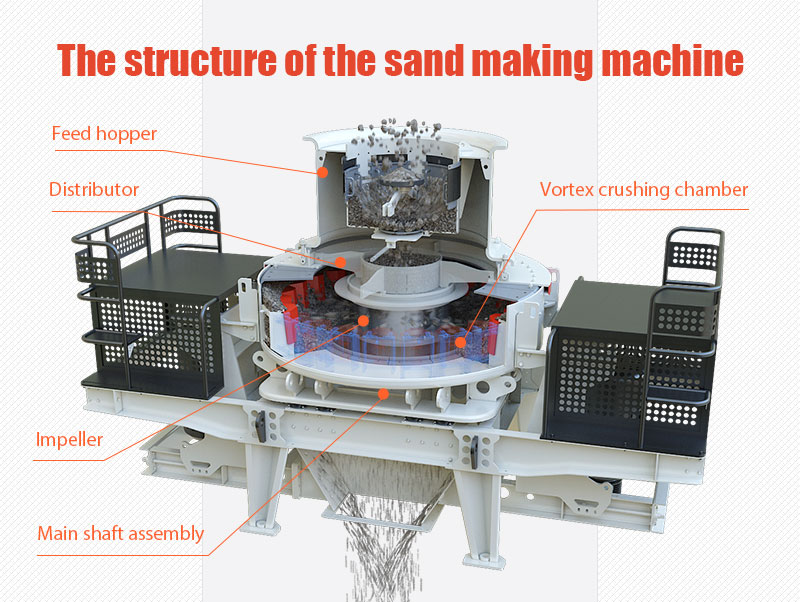

After secondary crushing, materials with a size of 20-80mm and a portion of the returned finished aggregate enter the sand shaping system. Its core function is to achieve "crushing + shaping + grading adjustment" to meet high-quality sand and gravel requirements. The core equipment is a vertical shaft impact crusher (impact crusher). Utilizing the "stone-on-stone" or "stone-on-iron" principle ("stone-on-stone" is used for hard rock to reduce wear, and "stone-on-iron" is used for soft rock to improve efficiency), the material is crushed to a particle size of ≤5mm while simultaneously improving the aggregate particle size (reducing the needle-like and flake-like content to below 10%). The sand making machine and four-deck vibrating screen (with mesh sizes of 5mm, 3mm, 2mm, and 0.075mm) form a closed-circuit system. Material above 5mm on the screen is returned to the sand making machine for further crushing. Material sizes of 5-3mm, 3-2mm, and 2-0.075mm are respectively sent to the finished product bin. Stone dust <0.075mm is collected separately. To flexibly adjust the finished product ratio (e.g., increasing the output of 3-5mm fine sand), a flap valve can be installed at the finished product discharge hopper to divert some 2-3mm material to the sand making machine's return conveyor for re-crushing and reshaping.

5. Finished Product Processing: Grading and Storage, On-Demand Transportation

After shaping, sand making, and screening, the material enters the finished product processing phase, where the core is "grading and quality adjustment." Finished products of different particle sizes (e.g., 5-31.5mm crushed stone, 3-5mm fine sand, 2-3mm medium sand, and 0.075-2mm fine sand) are stored separately in steel-structured finished product silos (each silo has a capacity ≥ 1 hour's production line output to prevent material mixing). A metered feeder at the bottom of the silo allows for mixing of finished products of varying grades according to project requirements. If the finished product's mud content exceeds the standard (>3%), a bucket wheel sand washer or spiral sand washer is added after screening. After cleaning, the finished product is recycled through a fine sand recovery machine to recover fine sand <0.16mm (with a recovery rate exceeding 85%), minimizing resource waste. Finally, the finished product is loaded onto trucks via belt conveyors or bulk loaders for continuous shipment.

II. Full System Equipment Configuration List (Taking a 500-ton-per-hour granite production line as an example)

| Process stage | Device Name | Model specifications | Core parameters / functions | Quantity | |

| Raw material pretreatment | Gripper vibrating feeder | ZSW490×110 | Processing capacity 200-400t/h, rod gap 50mm | 1 unit | |

| Drum stone washing machine | GT1530 | Processing capacity 150-300t/h, cleaning efficiency > 95% | 1 unit | ||

| Coarse crushing stage | Jaw crusher | PE1000×1200 | Feed port 1000×1200mm, discharge port 100-200mm | 2 unit | |

| Intermediate pile belt conveyor | DTⅡ ,B1200 | Conveying capacity 600t/h, length can be customized | 3 unit | ||

| Secondary crushing stage | Three-layer vibrating screen | 3YK2460 | Screen surface 2400×6000mm, processing capacity 400-600t/h | 1 unit | |

| Hydraulic cone crusher | HPT300 | Processing capacity 200-350t/h, discharge opening 15-30mm | 2 unit | ||

| Shaping and sand making stage | Vertical shaft impact sand making machine | VSI6X1145 | Processing capacity 200-300t/h, motor power 220kW | 2 unit | |

| Four-layer vibrating screen | 4YK3072 | Screen surface 3000×7200mm, processing capacity 500-700t/h | 2 unit | ||

| Flap valve | DN300 | Manual/electric adjustment to switch material flow direction | 4 unit | ||

| Finished product processing stage | Bucket sand washing machine | XSD3016 | Processing capacity 150-250t/h, cleaning degree> 98% | 2 unit | |

| Fine sand recovery machine | LZ250 | Recovered particle size ≥ 0.075mm, recovery rate > 85% | 2 unit | ||

| Finished product warehouse | Φ8×12m (cone bottom silo) | Single bin capacity 500m³, equipped with quantitative feeder | 4 unit | ||

| Assistance systems | Dust collector |

| Collect crushed and screened dust, with dust removal efficiency > 99% | 4 unit | |

| Centralized control system | PLC automation control system | Remotely monitor equipment operation and automatically adjust feed rate | 1 set |

III. Core Principles of Process and Equipment Configuration

Raw Material Compatibility: For hard rock (granite, basalt), a jaw crusher + hydraulic cone crusher + impact crusher is preferred. For soft rock (limestone, sandstone), a jaw crusher + hammer crusher + impact crusher can be simplified to reduce equipment investment.

Capacity Compatibility: The processing capacity of each link should be smaller at the beginning and larger at the end (e.g., feeder processing capacity > crusher processing capacity 10%, crusher processing capacity > screening equipment processing capacity 10%) to avoid bottlenecks.

Environmental Compliance: Crushing and screening stages must be equipped with pulse dust collectors, belt conveyors must be equipped with enclosed corridors, and sand washing wastewater must be recycled after treatment in sedimentation tanks and filter presses to meet "zero emission" requirements.

Flexible Adjustability: By adjusting the crusher discharge opening, screening machine mesh size, and flap valve flow direction, the finished product gradation can be adjusted as needed (e.g., 5-10mm for infrastructure construction and 2-5mm for precast components).

This process and equipment configuration produces high-quality machine-made sand and gravel aggregate with excellent particle shape, continuous gradation, and a controllable fines content (3%-15%), suitable for high-end infrastructure construction needs such as highways, bridges, and commercial concrete.